As with almost any laboratory process, scaling up an ultrasonic homogenization process comes with its nuances. While it would be nice to have a straightforward conversion chart for amplitude settings, the reality is, there’s going to be some trial and error.

This is due to the fact that larger probes behave somewhat differently to smaller ones. In this post, we’ll explain more about ultrasonic homogenizer amplitude and processing power and what it all means for scaling up.

Ultrasonic Homogenizer Amplitude

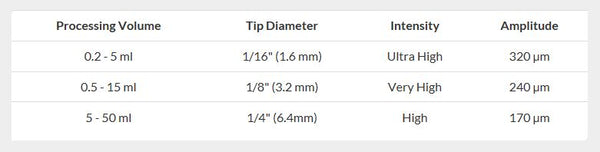

When you look at the specifications for the various probes available for a particular ultrasonic homogenizer model, you’ll see that each has a maximum amplitude associated with it.

Specifications for Q500 and Q700 Microtip Probes.

You might notice that the maximum amplitude decreases as the size of a probe increases. This is because it takes more energy to move a larger probe.

One of the things we need to bear in mind about amplitude is the nature of the settings. Ultrasonic homogenizer systems don’t enable you to set an actual amplitude. Rather, in most cases, you are setting the target percentage of maximum amplitude.

Another point worth mentioning here is that, if you’re processing something highly viscous, you might not be able to achieve the maximum amplitude.

Ultrasonic Homogenizer Processing Power

Based on amplitude alone, scaling up should be a fairly straightforward process. However, the total processing power using a given probe is dependent on both the amplitude and the surface area of the probe tip.

Different sized probes for various models.

Although you’ll get a lower amplitude with a larger probe, you have more surface area. You're imparting energy into a far larger volume and the "energy density" is lower. However, because the total energy being imparted is higher due to the much larger area, the result is still more total processing power and more energy being imparted into the system.

One way to visualize this is to think about the tip creating a cylinder as it vibrates. The frequency of vibration is constant for any given ultrasonic homogenizer, and that frequency generally doesn’t change among different models of the same brand. Therefore, the relative processing power of a given probe at a given amplitude can be thought of as relative to the size of the cylinder it creates when vibrating (the area of the tip of the probe multiplied by the amplitude).

To illustrate this, we can look at two different sized probes on the same homogenizer. For example, take the Q125 sonicator, using a ⅛” probe and a ¼” probe.

The volume of a cylinder (V) = πr2h. The height of the cylinder created is the amplitude. Comparing the two:

|

Probe |

Radius |

Amplitude |

Cylinder Size (V) |

|

⅛” (3175 µm) |

1587.5 µm |

180 µm |

π(1587.5)2 x 180 = 1.42 x 109 µm3 |

|

¼” (6350 µm) |

3175 µm |

120 µm |

π(3175)2 x 120 = 3.80 x 109 µm3 |

As you can see, there’s a big difference when you go up a size.

What This Means for Scaling Up an Ultrasonic Homogenization Process

Because larger probes behave differently than smaller ones, scale-up will always require some modification of the settings. Some trial and error may be needed to replicate the performance of a lower-power system processing a small volume with a smaller probe and high amplitude in a higher-power system with a large probe and lower amplitude when processing a large volume.