A rotor-stator homogenizer is a key piece of equipment in many processes, including creating emulsions, dispersions, and suspensions, disrupting or lysing cells, and homogenizing soft tissue.

For many rotor-stator homogenizer applications, once the desired result is achieved in the lab, the process needs to be scaled up. This could involve scaleup from a small laboratory batch to a larger one or to full-scale production batches. In the latter case, there will typically be multiple levels of scaleup, such as larger lab batches, pilot batches, and small production batches.

Unfortunately, there can be some tricky areas to navigate when scaling up a rotor-stator homogenization process, with multiple factors having an impact on the end result. Some of the potential consequences of an unsuccessful scaleup are:

- A product with too low or high a viscosity, leading to other issues in areas like filling, dispensing, or application

- Too small or large particle sizes or too large a range of particle sizes, for example, in a suspension

- Instability of emulsions, such as when two phases of a cosmetics product separate

- Textural issues, for example, a lumpy or aerated product

Aside from problems with the end product, scaleup processes could also suffer from other issues such as those related to time and cost.

Thankfully, armed with the right knowledge, it doesn't have to be a complete shot in the dark. In this post, we discuss some of the issues you might observe and the main factors to consider to make scaling up as successful as possible.

Factors to Consider When Scaling Up a Rotor-Stator Homogenization Process

We’ll explore these in more detail below but here are the main things to consider:

- Equipment available in production

- Vessel size and shape

- Position of the homogenizer

- Power and flow

- Shear and other forces

Let’s take a closer look at each of these factors:

1. Equipment Available in Production

Successful scaleup requires that you obtain the same result, but with different equipment. While the process will be similar, it might need to be tweaked along the way. Vessels, mixing apparatus, cooling methods, and transfer systems are often all different to what you would use in the lab. You also may not get the same number of options at the production level as you would in the lab.

Scilogex D500 Homogenizer Complete Generators and Rotors. You likely won’t see this level of choice in a production setting.

In some cases, it’s possible to get a scaled down unit of a production vessel for lab use, for example a Becomix Mini, which is which is built to mimic production equipment on a small scale. However, even with the process replicated as closely as possible, there will likely be some differences. For example, in the case of a Becomix, the pumping action of discharge is not replicated in small-volume lab units where the product will typically need to be removed from the vessel manually. This could have an impact on the properties of the final product, such as viscosity and texture.

Equipment doesn’t just differ between the lab and the production facility. There are various designs of vessels and other equipment in different production settings across the globe. This means that just because a process is scaled successfully in one facility, it doesn't mean the outcome will be the same somewhere else, even if the batch size is kept the same.

Lab scaleup and pilot batches are usually central to a successful scaleup. They enable you to foresee the types of issues you might encounter in a more cost-efficient manner. During this time, process engineers should be involved to help translate the process from one set of equipment to another.

2. Vessel Size and Shape

When we talk about vessel size, there are a couple of things to consider. One is the size of the homogenizer head versus the vessel size. A given probe will have a maximum volume over which it can work efficiently. If you use a head that is too small in production (or one that is too big in the lab), then you could run into issues such as insufficient mixing or particle size reduction.

Another factor is the ratio of batch size to vessel capacity. For example, when carrying out test scaleup batches, it may be tempting to avoid product waste by cutting the batch size. However, this isn’t a good idea as the batch-to-tank volume ratio (the volume of the batch compared to the maximum volume the tank can hold) can affect the final product. Potential problems include aeration, foaming, different mixing parameters, and hot zones on the vessel wall.

The vessel shape is also important. As Dickey discussed in detail in a 2005 article, tank geometry differences can cause issues in scaleup. For example, with a rotor-stator homogenizer process, you’ll often be going from a flat-bottomed glass or steel beaker to a production tank with a curved base. The change in the shape of the vessel can mean that product is incorporated differently and the end result changes.

As such, the mixing characteristics for each geometry change needs to be considered. In the article referenced above, Dickey outlines reasonable assumptions that can be made and provides calculations to help duplicate conditions in vessels that are not geometrically similar.

3. Position of the Homogenizer

When in a lab setting, you have options when it comes to the position of the homogenizer. It could be set up in a vertical position or at an angle. You could even use a range of positions during the course of mixing, particularly when using a handheld homogenizer.

A D500 Homogenizer and a handheld PRO250 Homogenizer.

When using a production vessel, the homogenizer head is usually fixed in a particular position, with the probe either protruding vertically from the center of the top of the vessel or at an angle. In some cases, the homogenizer enters the vessel from the bottom. There are also inline homogenizers used in flow-through processes. These can be difficult to mimic at the lab level, although there are lab inline homogenizers available from some manufacturers.

Aside from position, it’s important to bear in mind motion. At the lab level, you might be using a fixed homogenizer and moving the vessel or using a handheld unit and moving the homogenizer. Either way, it’s important to consider whether this motion can be mimicked in a scaled up process.

4. Power and Flow

To achieve the right particle size and other desired results, the flow rate should remain constant during scaleup. In many circumstances, a constant power per unit volume will deliver the same flow rate. However, as discussed by Thapar in a Tech Trends article, this only applies if there is turbulent flow.

With some applications, especially the processing of high-viscosity materials, the flow is laminar rather than turbulent, and as a result, there is more viscous shear (more on that below). As Thapar outlines, the type of flow can be determined by the relationship between the power draw of the unit and the rotational speed.

5. Shear and Other Forces

It’s often difficult for production equipment to replicate the same level of shear and other forces as laboratory equipment can. What’s more, various forces are at play during homogenization and the combination of these is not entirely understood.

What we do know is that as the homogenizer tip turns, it imparts energy on the surrounding product. Then when the product is forced through the stator, it undergoes shear stress. The level of shear is affected by the speed as well as the size of the gap between the rotor and the stator. As such, any changes in those ratios need to be compensated for.

When we talk about speed, it’s not the RPM of the motor we should be concerned about, but rather the tip velocity of the rotor. The speed of the rotor relates to the RPM by the following equation:

V = Rπd/60

Where:

- V = rotor speed (m/s)

- R = RPM (rev/min)

- d = rotor diameter (m)

In principle, when you double the rotor diameter, the RPM value should be halved to maintain the same tip velocity, and so on.

However, in practice, the level of shear imparted by a given rotor at a specific cannot be predicted by an equation. Due to this, many manufacturers provide shear numbers or curves based on real testing or complex calculations, which will help when scaling up.

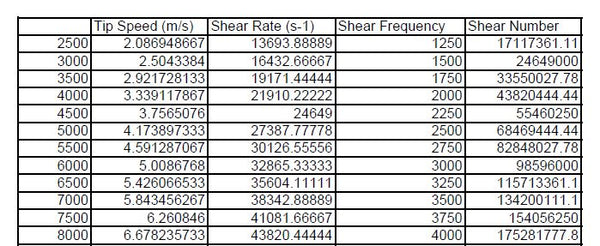

For example, below is a section of a shear table for a Pro Scientific 20mm probe (the first column is RPM). The numbers are derived from a formula that takes into account a variety of factors, including the speed, the distance between the rotor and stator, the size of the teeth, and the number of openings. Similar tables are provided for the other probe sizes.

As mentioned, other forces than shear are at play. For example, while cavitation is generally associated with an ultrasonic homogenization process, it is also instrumental in rotor-stator homogenization processes. Achieving the same level of cavitation as you do in a small-scale environment can be difficult in a production setting. Cavitation size needs to increase with intensity staying the same.

Final Comments

Clearly there are some complex factors to consider when scaling up a rotor-stator homogenization process. That being said, it may not be necessary to study every one of these areas in-depth from the get-go. Depending on the application, much of the scaleup process can involve trial and error. Oftentimes the process is scaled using a set of base parameters and these are tweaked to achieve the desired end result. In this case, knowledge of the above factors and how they can affect mixing can help a great deal.

It’s also worth noting that not every scaleup process is reliant on human calculation. Automated systems or simulation software can help with making more accurate predictions. For example, if automated systems are used at the lab stage and there are scaleup versions of that equipment available, manufacturer testing and the resulting guides will help greatly in scaling up.

As for simulation software, this used to be mainly associated with basic mixing using stirrers, but there is newer software available for homogenization processes. For example, VisiMix RSDE is designed specifically for modeling rotor-stator homogenizer processes.