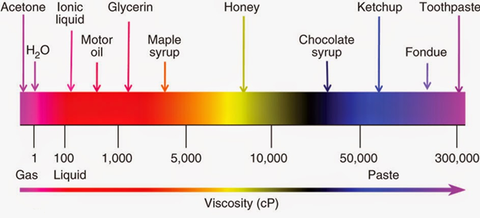

The viscosity of your material will influence the effectiveness of its homogenization. Generally, the higher the viscosity the lower the efficiency of homogenization. Viscosity ratings for your homogenizer are often given in centipoise (cP) or millipascal-second (mPas; 1 cP = 1 mPas). Ratings can vary from 1000 cP for simple hand held rotor-stator homogenizers to 10000 cP for high power bench top models. To quickly estimate the viscosity of your sample, you can compare it with the known viscosity of common materials shown in the scheme below and see how that compares to the viscosity rating of your homogenizer.

Viscosity scale of common materials

The effect of viscous materials on homogenization depends on the type of homogenizer used but is generally true that the higher the output power the better the mixing of more viscous materials. For probe-based homogenizers (ultrasonic or rotor-stator) the volume which can be efficiently processed decreases significantly (up to an order of magnitude) with increasing viscosity. Mixing cycles should also be kept as short as possible (3 min. max) to avoid overheating of the motor.

Generally, the effectiveness of rotor-stator homogenizers quickly decays with increasing viscosity. 10000 cP is usually the maximum viscosity processable with rotor-stator homogenizers. To improve mixing of viscous samples separate probe heads can be used. For example, the PRO scientific deflector heads are specially designed to enhance homogenization of higher viscosity materials. It is advisable to move the rotor-stator around as much as possible so that all areas of the viscous materials are mixed.

Ultrasonic homogenizers are somewhat less affected by the viscosity of your material. They rely on pressure waves which create bubbles. The collapsing of these bubbles creates energy that disrupts the material and allows mixing. Materials with increased viscosity move less easily than more watery ones and therefore put pressure on the bubbles making the mixing more efficient. This, however, only works till a certain viscosity. If your material gets too viscous, it cannot be effectively processed. A good rule of thumb is that “if you can’t pour it then you can’t sonicate it”.

Bead mill homogenizers are much less suited for viscous materials as they use beads to homogenize the material. If the beads can’t freely pass through the material, they can’t homogenize it.

High pressure homogenizers use high pressure to force your sample through small slits. For them to work properly, your sample should be fluid enough to be effectively pumped.

There are a view tricks to overcome some of the difficulties in homogenizing viscous samples and to process high viscous materials without significantly decreasing the effectiveness of your homogenization. A material’s viscosity is decreases with increasing temperature. Therefore performing the homogenization at higher temperatures will generally provide better mixing results. It is important to check the decomposition temperature of your material before homogenizing it at higher temperatures so that you do not destroy your sample. Another way to decrease the viscosity of your material is by addition of surfactant and emulsifiers. These can break up the internal resistance and allow the material to move more freely and thus become less viscous.

No matter what type of homogenizer you use, mixing viscous materials will always be more difficult than mixing watery mixtures. You can account for this by processing smaller batches of material and, for handheld devices, moving the mixture head more rigorously to enhance homogenization. Alternatively, you can increase the processing temperature or add surfactants and emulsifiers to your sample to decrease its viscosity.