While we often hear about shear forces in rotor-stator homogenization and cavitation forces in ultrasonic homogenization, in reality, most types of homogenization processes involve a combination of multiple forces.

You may also come across mention of impact forces, as well as the driving factors behind some forces, including pressure and turbulence. In this post, we explain what these forces are and in which types of homogenization they are most prominent.

Shear

Shear forces are unaligned forces pushing in different directions. When these are applied to your sample, they can facilitate things like mixing, emulsification, particle size reduction, dispersion, and cell lysis.

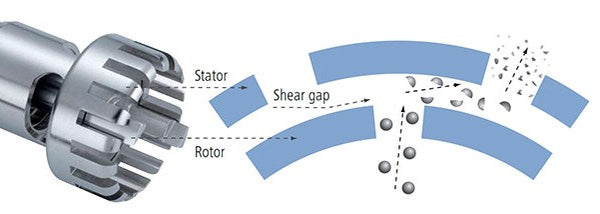

Shear forces are key in rotor-stator homogenization. In this process, a metal shaft (rotor) rotates inside a stationary casing (stator). The sample is drawn into the narrow space between the rotor and stator.

Image source: IKA

The laws of fluid mechanics state that the velocity of the fluid immediately adjacent to the rotor is the same as the velocity of the rotor. Meanwhile, it follows that the velocity of the fluid immediately adjacent to the stationary stator is zero. This results in a high velocity gradient in the small gap between the rotor and stator, and subjects the sample to high shear forces.

Shear forces are also a factor in high-pressure homogenization. In this case, the pressure exerted on the sample pushes it through a valve or membrane, subjecting it to a combination of forces, including shear.

Cavitation

Pressure changes during homogenization can cause the formation of bubbles in liquid samples. These bubbles (cavities) grow and eventually implode. The whole process is known as cavitation.

When the bubbles implode, a large amount of energy is released. Collapsing bubbles within the liquid transfer kinetic energy to surrounding liquid particles, creating high-speed jets of liquid that can break apart or erode the surface of particles. Bubbles that collapse on the surface of particles transfer energy directly to the particle, breaking it apart or causing surface erosion.

The turbulence within the liquid that results from cavitation can also result in strong impact forces when particles violently collide.

Cavitation is most commonly discussed in the context of ultrasonic homogenization, but it is also a factor in high-pressure homogenization.

The video below shows an ultrasonic homogenizer in action:

The cloudy appearance of the liquid close to the probe is caused by the formation and collapse of microscopic cavitation bubbles.

Impact

During homogenization, particles are traveling at high speeds. When particles collide with one another, the force of the impact may be enough to erode the surface of the particle or facilitate complete breakup of the particle or an agglomerate. This is a factor in all types of homogenization involving particles traveling at high speeds.

Impact forces can also result from collisions between the sample and the vessel, or with other solid components, such as beads (in bead mill homogenization).

This video shows a BeadBlaster™ 24 bead mill homogenizer in action:

Main Forces Involved in Each Type of Homogenization

Although most types of homogenization involve multiple forces, here is a summary of the major forces at play and how these might impact your decision of which type of homogenization to use.

|

Type of homogenizer |

Main forces |

Considerations for applications |

|

Main: Shear Other: None |

|

|

|

Main: Cavitation Other: Impact |

|

|

|

Main: Shear, impact, and cavitation, depending on design |

|

|

|

Main: Impact Other: Shear |

|

|

|

Paddle Blender (Stomacher) |

Main: Impact Other: Shear |

|

|

Main: Impact Other: Shear |

|