Rotor-stator homogenizers are used in a broad range of applications, including creating emulsions, homogenizing soft tissue, particle size reduction, and more.

No matter what your application, proper cleaning of your homogenizer is essential to keep it in good working order, as built-up residue could cause the probe to seize. Plus, in some situations, your application may call for very thorough cleaning of equipment to sterilize the homogenizer and to prevent cross-contamination of samples.

A rotor-stator homogenizer is a relatively expensive piece of equipment. To make the most of your investment, you'll want to keep up with maintenance of your unit to prolong its lifespan.

In this post, we’ll explain some of the options you have when it comes to cleaning methods as well as best practices for maintaining your rotor-stator homogenizer.

Cleaning a Rotor-Stator Homogenizer

As mentioned, when it comes to cleaning, the method you should use will depend on your application. For example, if you’re working with large particle sizes, there’s a chance that fragments from your sample could become lodged in the generator probe (sometimes referred to as the dispersing element), requiring a more forceful cleaning method.

If you need to sterilize the instrument, you’ll have to take measures to ensure that the entire area that will be in contact with the sample is completely free of residue. It’s common for bacterial cultures to form in the grooves of the probe if it’s not cleaned and dried properly.

Here are the most common cleaning methods for rotor-stator homogenizer generator probes:

- Solvent rinse

- Disinfectant or chemical sterilization

- Steam jet (humid heat)

- Ultrasonic bath

- Autoclaving

Let’s look at each of these in more detail.

1. Solvent Rinse

If your application doesn’t require sterilization, you may be able to get away with simply cleaning the head in an appropriate solvent between uses. For example, if you’re homogenizing multiple samples with the same or similar composition, you could simply use the same solvent to remove most of the residue between samples.

Even if you’re going to be using another cleaning method afterwards, it’s a good idea to operate the unit in an appropriate solvent in order to remove the bulk of particles. This should be done as soon as possible after use to avoid materials drying onto the components. You won’t have to dismantle the unit for this type of cleaning.

2. Disinfectant or Chemical Sterilization

After use or between uses, you may need more thorough cleaning. Disinfecting the probe can help ensure that you avoid cross-contamination and that bacteria cultures won’t build up in the grooves of the dispersing element.

One of a selection of dispersing elements for the Ultra-Turrax® T 25.

Germicidal solution, like alcohol, phenol, and formalin are common choices. Bear in mind that some chemicals can remain on the components, so after chemical cleaning, you should operate the unit in sterilized water to rinse off residual chemicals and then allow it to dry. Otherwise, you could end up contaminating future samples with the disinfectant chemicals or cause corrosion of the probe’s components.

You could leave the dispersing element attached to the motor unit for this method of cleaning and operate the probe in the germicidal solution. Alternatively, you can remove and disassemble the probe and immerse all components in the disinfectant, using a cloth or brush to remove residue as needed.

3. Steam Jet (Humid Heat)

If you require more thorough cleaning, a steam jet may be the solution. In this case, pressurized steam is used to sterilize the equipment and help remove particles lodged in the components. The dispersing element has to be removed from the motor unit for this type of cleaning.

4. Ultrasonic Bath

One more method that may be called for in some situations is the use of an ultrasonic bath. In an ultrasonic bath, energy is spread throughout the bath liquid causing bubbles to form. The formation and popping of these bubble can force contaminants off the surface of the generator probe parts.

A Branson DHA-1000 Industrial Ultrasonic Cleaner and a Bransonic 0.5 Gallon Ultrasonic Bath.

This type of cleaning also requires removal of the generator probe from the motor unit. A pre-soak in enzymes is often part of the ultrasonication process.

5. Autoclaving

If more thorough sterilization is required, then autoclaving the parts might be an option. Hot air at 120–190°C (depending on your application) can ensure nothing lives on the components. Bear in mind that one or more of the above steps (such as cleaning in a solvent and ultrasonic cleaning) may need to be carried out prior to autoclaving to ensure all residue is removed from the parts. If not, autoclaving could simply bake on the residue.

Cleaning the Motor Unit

While the above cleaning methods have focused on the generator probes, it’s important not to forget about the motor drive housing. Whether you’re using a handheld homogenizer like the PRO250 (below left) or a benchtop model like the PRO400 below (right), the motor unit will need some cleaning.

When focusing on the probe, it’s easy to forget about the the area where the probe attaches to the motor. Residue can build up around the bearings, potentially causing the instrument to seize up or the motor to prematurely wear due to the additional torque required to drive the rotor.

In addition, dust and debris from the environment as well as splashing samples can quickly make the entire surface of the motor unit dirty, so it’s a good idea to wipe it down between uses. Using a mild detergent is advised by many manufacturers while solvents are not recommended.

Maintenance of Rotor-Stator Homogenizers

Using and caring for your homogenizer properly can not only keep it in good working order for longer, but it can also ensure you keep yourself safe and don’t damage your unit. Cleaning the unit is one of the most important things you can do to keep it in good working order, but here are other areas where rotor-stators may require maintenance:

Replace Bearings As Needed

Some models will come with Teflon bearings that prevent liquid from entering the unit and stop the rotor and stator rubbing together. These may need replacing over time. A good way to tell that a bearing needs replacing is if it has become discolored or if there is an increase in noise (more than usual) while the unit is in operation.

Lubricate Threads As Instructed

Threads of all connecting threaded parts need to be lubricated for certain units and some even include a tube of lubricant when you purchase the machine. Typically, no moving parts should be lubricated.

Many models come with sealed ball bearings in the motor unit. These typically don’t need additional lubrication, but consult your manual to check.

Replacing the Motor Brushes

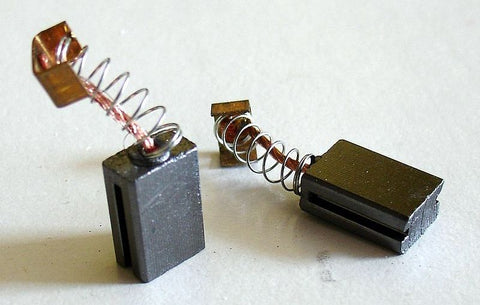

The one major piece of maintenance that you will likely need to carry out at some point is carbon motor brush replacement (unless you have a unit with a brushless motor). The motor brushes conduct the current between the stationary wires and moving parts. These wear over time, and you’ll likely know that one needs replacing because the motor unit will fail to operate.

An example of a pair of carbon motor brushes.

Motor brushes come in pairs. Even if it looks like only one needs replacement, both should be replaced at the same time. This is a fairly technical repair and can be done by the manufacturer. In the event that you have the technical expertise to replace the motor brushes yourself, ensure you use original spare parts for that motor and ensure the unit is not connected to the power supply when you replace the brushes.

You should never attempt to replace the motor brushes if the homogenizer is still under warranty, as it would void the warranty. So long as the instrument was not misused, the warranty will almost certainly cover the repair or replacement of the motor or the brushes.

Only Use Manufacturer-Approved Parts

Parts for any homogenizer are almost never cross-compatible with others. If you’re missing a part for one unit, it might be tempting to simply replace it with a part from a similar model, either because you have it on hand or it is less expensive. Aside from almost certainly not working properly, this could damage your machine and may even render it unsafe to operate. Any damage would not be covered under warranty, as it would be considered improper use of the instrument.